Automated Bulk Part Supply Equipment & Pre-feeders

CDS Lipe Automated Bulk Part Supply Equipment

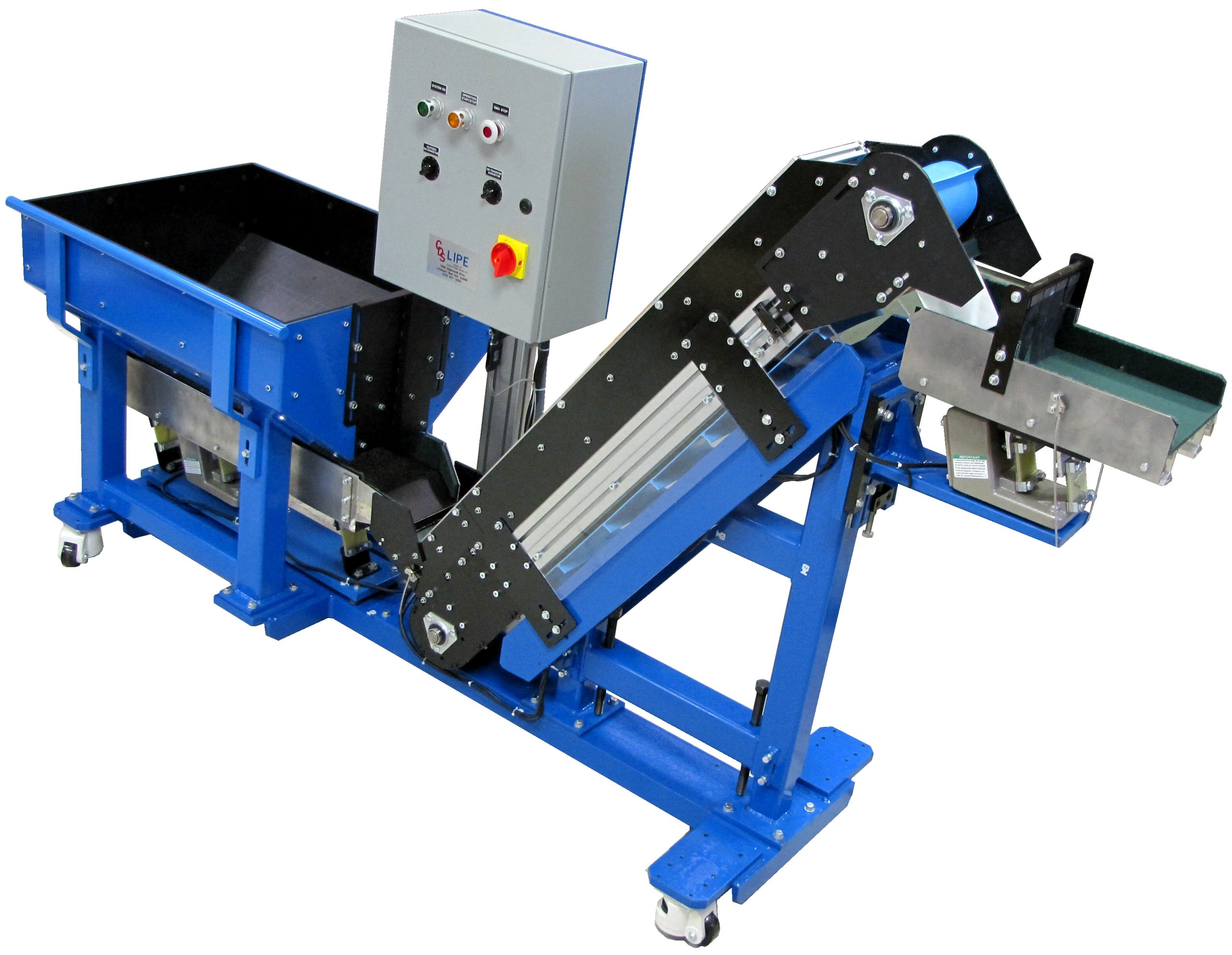

CDS LIPE Intelligent automated bulk part supply systems are critical to the performance of feed systems and downstream automation. Pre-feeders eliminate the hazards associated with your operators manually loading heavy parts or materials. Automated bulk part supply systems are designed to supply parts, packages or materials from hopper or storage container and meter those parts, packages or materials to a secondary operation on a demand basis

For a process engineer, the value of CDS Lipe Automated Bulk Part Supply Equipment isn't just in "moving parts"—it’s in the optimization of the OEE (Overall Equipment Effectiveness) equation. These systems serve as the buffer and the pace-setter for the entire downstream assembly or packaging process.

1. Ergonomic Safety and Labor Optimization

In a manual loading scenario, the "human element" introduces variability and physical risk.

Injury Mitigation: Pre-feeders eliminate the repetitive strain and acute injury risks associated with lifting bulk containers (gaylords, bins, or crates) to reach elevated hopper heights.

Strategic Labor Allocation: By utilizing a large-capacity bulk supply system, you shift the operator's role from a "material handler" to a "process technician." Instead of constant manual replenishment, the operator monitors the health of the line, performing high-value tasks while the equipment handles the bulk logistics.

2. Decoupling and Buffer Management

The primary engineering benefit of a CDS Lipe system is its ability to decouple the bulk storage from the precision feeding operation (such as a vibratory bowl or centrifugal feeder).

Head Load Consistency: A common failure point in feeder bowls is "head load" variability—where the weight of too many parts in the bowl dampens vibration and slows down the feed rate.

Demand-Based Metering: Automated supply systems use level sensors (laser, ultrasonic, or proximity) to maintain an optimal "sweet spot" of inventory in the secondary feeder. This ensures a consistent feed rate ($parts/minute$) regardless of how full the main bulk hopper is.

3. Preservation of Part Integrity

For process engineers dealing with finished surfaces or delicate geometries, the "drop" matters.

Controlled Discharge: CDS Lipe systems are engineered to minimize part-on-part impact. By metering the flow, you prevent the "crushing effect" found in overfilled hoppers.

Reduced Recirculation: Because the system only supplies parts on demand, components spend less time vibrating or tumbling in the secondary feeder, significantly reducing cosmetic scuffing or structural fatigue before they ever reach the assembly stage.

4. Maximizing Downstream Uptime

Downstream automation is only as fast as its slowest input.

Autonomous Run-Time: A well-integrated bulk supply system extends the "walk-away time" for a cell. This allows the production line to absorb upstream supply chain hiccups without starving the high-speed assembly or packaging machines.

Smooth Transitions: By utilizing variable speed drives and intelligent metering, these systems eliminate the "slugging" of materials, ensuring a laminar flow of parts into the orienting equipment.

- Pan Feeders with Automatic Metering

- Tote Dumper

- Drum Dumpers

- Pallet Dumpers

- Wire Basket Dumpers

- Dunange Dumper

- Soft Sided Box Dumper

- Gaylord Dumper

- Drop Bottom Container-Automatic Unload Equipment

Technical Summary for Process Planning

| Feature | Process Impact | Engineering Benefit |

| Level Sensing | Feedback loop integration | Constant feed velocity; reduced bowl wear. |

| High-Volume Hopper | Increased buffer capacity | Higher MTBM (Mean Time Between Maintenance/Intervention). |

| Demand Metering | Precision mass flow control | Prevention of downstream jams and "bridging" in chutes. |

Pre-Feeders are available to gently handling a quantity of parts and gently metering them to downstream process.

Dunnage Dump System

Automatic Tote or Tray Dumper

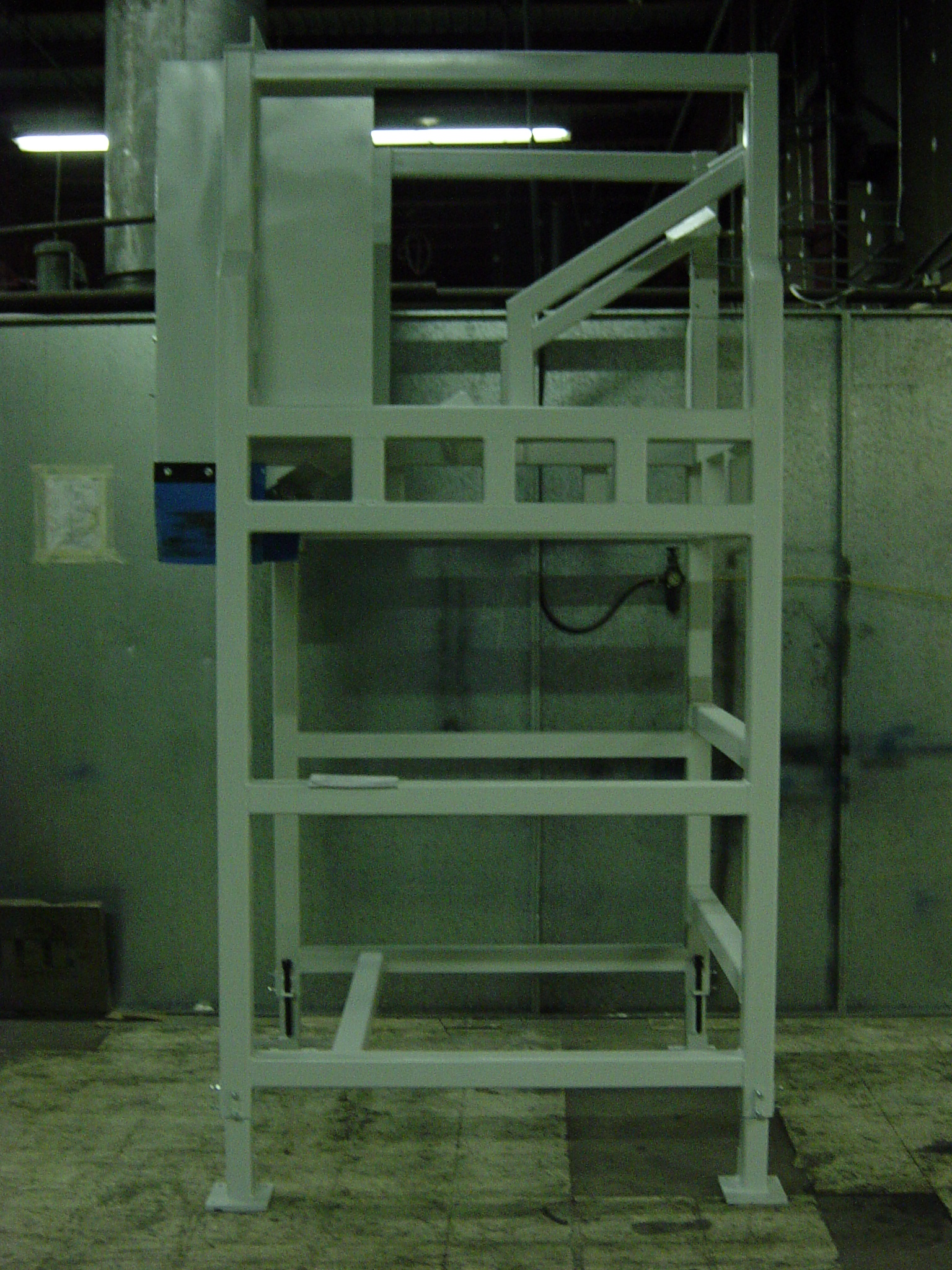

Drop Bottom Stand & Automatic Unloader

2000 lb Drop Bottom Container Stand & Unloader 4000 lb Drop Bottom Container Stand & Unloader 6000 lb Drop Bottom Container Stand & Unloader

Pan Feeder bulk supply w/ Manual of Automatic Flow Gates