Part, Package & Materials Handling Solutions

Dyna-Slide-Gentle Part Feeding & Materials Handling Equipment & Systems

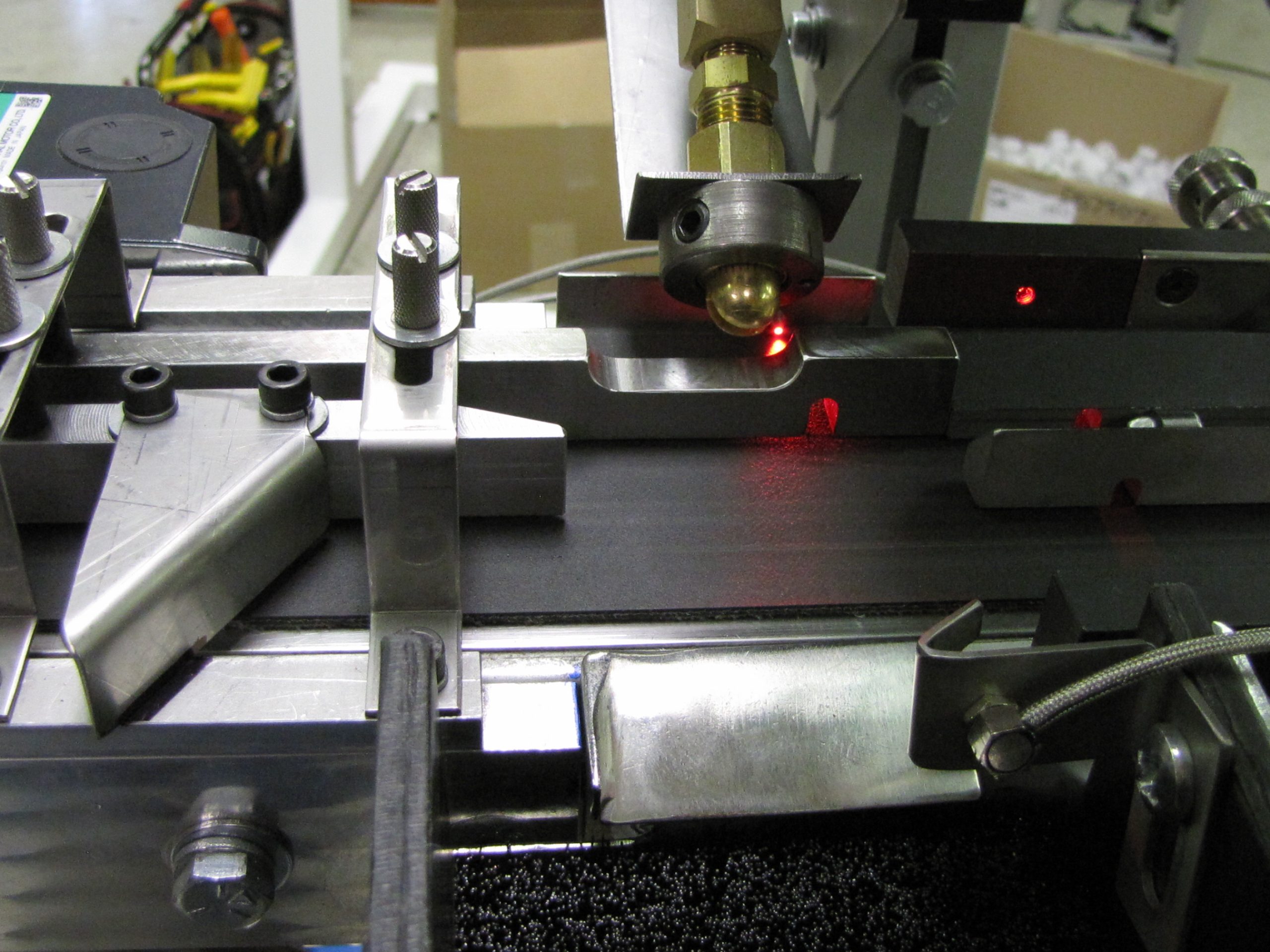

Dyna-Slide vibratory parts feeders, conveyors and accumulators are an efficient means of gently handling parts, packages or materials. Dyna-Slide parts feeders can handle a wide size range in a single feeder with quick change tooling and excellent for large, long or heavy parts. Dyna-Slide parts feeders utilize directional vibratory feeder brush, a quiet, gentle, robust and proven technology. Since 1972 Dyna-Slide has been the market leader in gentle handling vibratory feeders with thousands of machines in use worldwide. CDS LIPE has designed and built linear vibratory parts feeders for the following applications: light bulb filament feeders, nuclear fuel rod feeders, magnet feeders, powdered metal parts feeders, pin feeders, eye glass stem feeders, pharmaceutical feeders, 'S' hook feeders, dome switch feeders, seat belt bracket feeders, clip feeders, roller bearing feeders, ball bearing sorters, bearing race feeders, tapered bearing cage feeders, sleeve feeders, brass fittings feeders, ceramic fuse body feeders, o-ring feeders, cosmetic jar orientation, cap accumulation, green powder metal part feeding, sintering press loading, press load/unload, plastic parts feeders, motor housing feeders, spring feeders, cup feeders, light bulb feeders, valve seat feeders, ceramic blank feeders, lid feeders, plastic parts feeders, handle feeders, blade feeders, bushing feeders, mascara brush feeders, and more...Known for our expertise in soft handling let us put that experience to work for you.

Flexible feeder systems supply parts, packages or materials to vision guided robots. May create distribution patterns to maximize robot efficiency and speed. A significant trend in part feeding automation in recent years is flexible feeders for both large and small parts, packages or materials. These automated systems are designed to distribute parts, packages or materials "on demand" to vision guided robots. CDS-LIPE flex feeders are available for the smallest dimensional parts or family of parts to the largest.

Dyna-Feed -Part Feeding Materials Handling Equipment & Systems

CDS-LIPE focus is to provide automated materials handling systems. We provide the best solution for each application which may include Belt Feeders, Rotary Accumulators, Step Feeders, Vibratory Bowl Feeders & Centrifugal Feeders, Roll Sorters, Multi Track Orientors and a wide variety of pan hoppers, belt hoppers and automated bulk supply systems to provide integrated systems handling munitiones, nut feeders, bolt feeders, syringe orientation, sprue separators, billet feeders, forged part orientation, press load systems, caste part orientation systems, plier feeders, screw driver assembly, pipette orientation, machine tool load systems, machine tool part accumulation, pouch feeding, cam orientation systems, stamping press automation to name a few.

Automated Bulk Part Supply Equipment & Pre-feeders

Integrated part feeding automation requires automatic bulk supply systems. CDS-LIPE produces automatic dumpers, tote dumpers, drop bottom container unloaders, dunnage unloaders, drum dumpers. Each designed for integration to supply part, package or material to feeders or other upstream machines, assembly lines and robots on demand.

Machine Loading Devices, Equipment & Systems

Machine Tending Robots: Machine tending refers to overseeing a machine while it performs a job, as well as the process of feeding parts in and out. Machine tending can be dull and dangerous work that requires a high level of consistency. Robots are well-suited for this type of work. They tend all kinds of machines from presses and shears to injection molding machines. Machine tending automation developed to keep workers safe from the tedious, injury-prone tasks. CDS-LIPE loads a wide variety of machines. These include standards such as centerless grinder feeders. A wide variety of load tracks, singulation escapements, Cross Shuttles, Lifts, Walking Beam Loaders, Servo Linear Rams, Pick & Place , Pallet Loading, Dial Loading, side grinder loading, centerless grinder loading, horizontal grinder loader, furnace loader, tray loader, coin press load, coin press unload

Conveyor types available: Super low profile belt conveyors for "in process" applications, medium capacity belt conveyors for robot pick belts. Can be configured as index belts, minimum back pressure transport applications and incline belts. Custom index chain conveyors for positioning applications and heavy duty conveyors for transport and accumulation applications. Incline conveyors, decline conveyors are available for every industrial environment including USDA-FDA applications.

System Integration, Assembly Automation & Specialty Machines

Integrated Materials Handling & Part Feeding Systems. Distribution of parts, packages and materials to Vision System , machine tending, automatic and semi automatic part presentation to assembly operations. Part Stocker Bulk Part Storage Feeders Feed & Orientation Part Presentation & Loading

Sanitary & Washdown Duty Automation Equipment & Systems

CDS-LIPE Sanitary Group designs & build wash-down duty parts feeders and sanitary equipment since 1989, Sanitary conveyors comply with latest USDA, Canadian Dairy and AMI standards. Package handling, food packaging orientation for, pharmaceutical applications.

Part & Materials Physical Separation & Sortation

Dimensional Sortation & Screening Equipment Plastic Sprue, Gates, Runner and Over Separation Casting Sprue, Gates, Runner and Over Separation

Vision Based Sortation, Selection or Orientations Systems

CDS-LIPE provides parts feeders with vision sortation, vision based orientation, vision based pattern formation, and vision based inspections systems. Vision technology allows even the most complex parts to oriented and evaluated for quality at any stage in the manufacturing process.

Medical, Diagnostic Component Assembly

CDS-LIPE provided automated materials handling from bulk supply and orienting of medical components, pharmaceutical packaging, personal care products, orthopedic implants, diagnostic components for assembly.

Gentle Automated Materials Handling

CDS-LIPE material handling products are used worldwide to gently transport, feed, orient, accumulate a wide range of parts, packages and materials that a physically fragile and or have finished surfaces. Glass bulb, ceramic parts, machined parts accumulation, feeding, orientation.

Gentle Materials Handling Automation for Bearing, Electrical, Electronics, Powdered Metal, Consumer Tools, First Tier Automotive, Second Tier Automotive, Truck, Aircraft, Building Supplies, Munitions, Battery, Energy, Modling, Tire Products, Aerospace, Appliances, Caste & Forge Industries