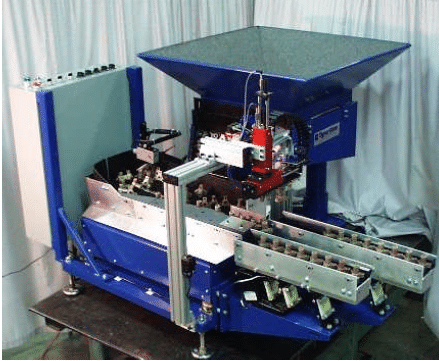

Small Part Flex Feeder

FLEX FEED PROCESS :

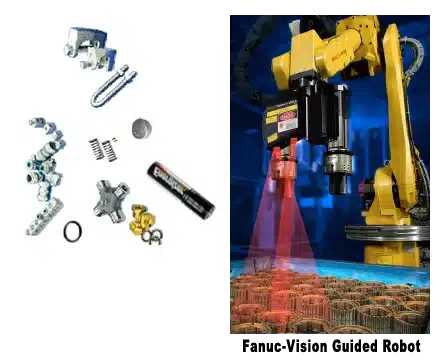

Flex Feed systems feed wide variety of parts or packages with features or geometry not favorable for standard feeders from bulk supply and gently distributes parts to operators or vision guided robots.

Flex Feed process is scalable to part dimensions, weight and throughput

May be used as a “pick field of view” or “pick on the fly” methodology

Integrated to or stand alone from downstream or upstream processes

FLEX FEED PROCESSING BENEFITS

Positive part, package or materials distribution to pick process.

Gentle, package or material handling uses none marking tooling

Autonomous operation with simple I/O Interface

Available with vibratory belt configurations

Handles Families of Parts with a single feeder

Zero drop, simple recirculation of parts

Available in a wide range of configurations

Small part Flex Feeders are cost effective, gentle solutions for randomly distributing parts for vision inspection or vision guided robot handling. Most often employed when part, package or material geometry is not favorable for traditional feeders. Small parts or families of small parts can be fed in a single flex feeder. Each system consists of a supply hopper which meters parts, packages or material to part distribution surface which creates the part flow pattern. Surface may be vibratory pan with tooling, a bruchlon conveyance belt conveyor. Passive and active tooling may be used to create maximum part, package or material distribution. Multiple hopper types, distribution methods, conveyor surfaces and vision processing surfaces are available for difficult or fragile parts. Parts can often be properly oriented during return cycle reducing recirculation and increasing throughput. Standard assemblies and custom solutions are available.

CDS-LIPE FLEX FEED APPLICATIONS