An Expert Overview For high-volume assembly lines, the selection of a feeder is critical to achieving peak Overall Equipment Effectiveness (OEE). The best solutions blend speed, accuracy, and versatility to handle millions of components per year. As a Premier Automated Material Handling Systems Expert, CDS-LIPE recognizes that the ideal choice is often a custom solution that integrates the advanced capabilities … Read More

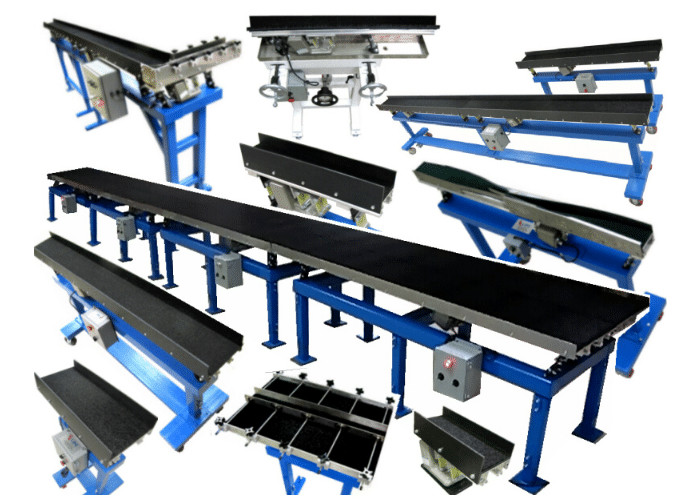

What do Vibratory Conveyors do?

Vibratory Conveyors: The Foundation of Consistent Material Flow Vibratory conveyors are robust material-handling equipment essential for transporting bulk products, parts, and materials across a wide range of industries. They function by using controlled vibratory force to gently move fine to coarse-grained bulk materials, ensuring a consistent and uninterrupted flow into subsequent manufacturing processes. CDS Lipe is an expert manufacturer, designing … Read More

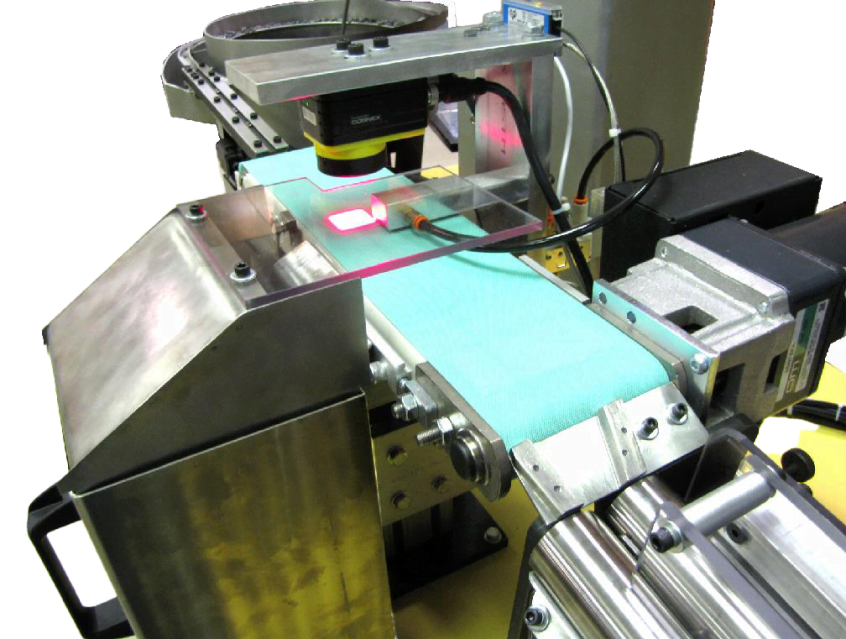

Sorting Machines

Precision and Quality in Automation Sorting machines are the final arbiters of quality in an automated production line. These sophisticated systems are engineered to inspect and categorize products or parts at high speeds, ensuring that only components meeting strict quality standards move forward. At CDS-LIPE, we design and build custom sorting machines that provide an essential layer of quality control … Read More

Accumulators

Accumulators: The Buffer for Seamless Production Accumulators are vital components in automated production lines, acting as a temporary storage buffer for products or parts. They are designed to absorb fluctuations in the speed of an assembly line, preventing downstream equipment from being starved of materials or from being overwhelmed. This buffering capability is essential for maximizing efficiency and ensuring continuous, … Read More