Precision and Quality in Automation

Sorting machines are the final arbiters of quality in an automated production line. These sophisticated systems are engineered to inspect and categorize products or parts at high speeds, ensuring that only components meeting strict quality standards move forward. At CDS-LIPE, we design and build custom sorting machines that provide an essential layer of quality control and efficiency for your manufacturing process.

What are Sorting Machines?

A sorting machine is a system that automatically inspects and separates products based on a pre-defined set of criteria. Unlike simple feeders that just orient parts, a sorting machine uses advanced technology to evaluate each item for flaws, dimensions, and other critical characteristics. Items that pass the inspection are directed to one location, while those that fail are rejected and sent to another.

CDS-LIPE’s sorting machines incorporate a variety of cutting-edge technologies to achieve this precision:

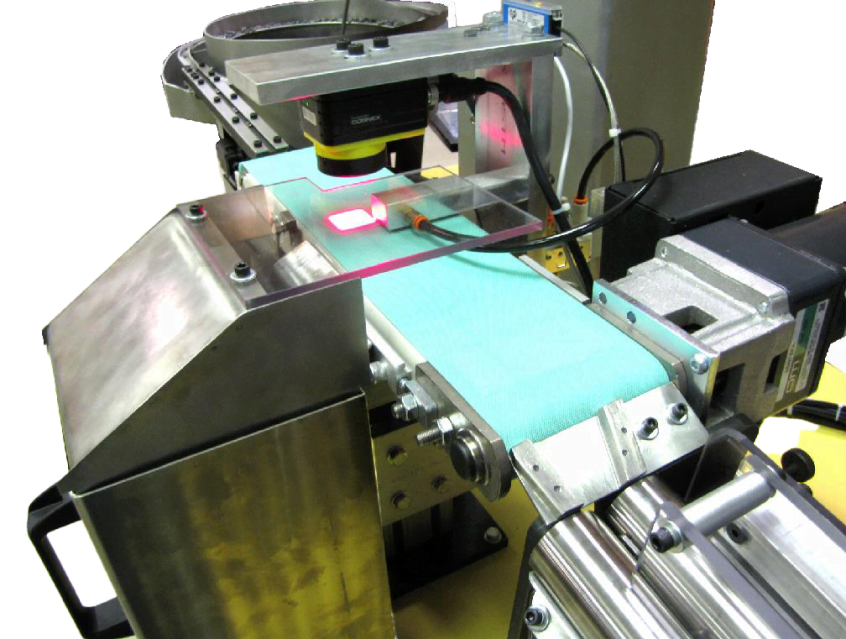

- Vision Inspection: High-speed cameras capture images of parts, and software analyzes them for surface defects, incorrect orientation, or missing features.

- Laser and LED Measurement: Laser and LED systems measure dimensions with extreme accuracy, checking for correct length, diameter, and shape.

- Eddy Current Inspection: This non-contact technology detects material flaws, cracks, or variations in metal properties.

- Ultrasonic Inspection: Sound waves are used to detect internal flaws or structural inconsistencies in parts.

How are they Used?

Sorting machines are essential for any industry where product quality and consistency are paramount. They are used to perform a wide range of inspection tasks that would be impossible or impractical to do manually.

Key uses include:

- 100% Quality Control: By inspecting every single part, sorting machines eliminate the risk of defective products reaching the consumer, which can prevent costly recalls and protect a brand’s reputation.

- Defect Detection: They can identify defects like incorrect thread counts, counterbore depths, mixed materials, or subtle surface imperfections at speeds of hundreds or even thousands of parts per minute.

- Feature Verification: Sorting machines confirm the presence and correct placement of critical features, such as holes, slots, or threads, on a component.

- Automated Sorting: They can sort mixed batches of parts by size, shape, or material, automating a task that would otherwise require significant manual labor.

In essence, sorting machines transform raw data from a sensor into a binary decision—”pass” or “fail”—that ensures the integrity and reliability of your final product.

Let’s talk about your project – contact us.