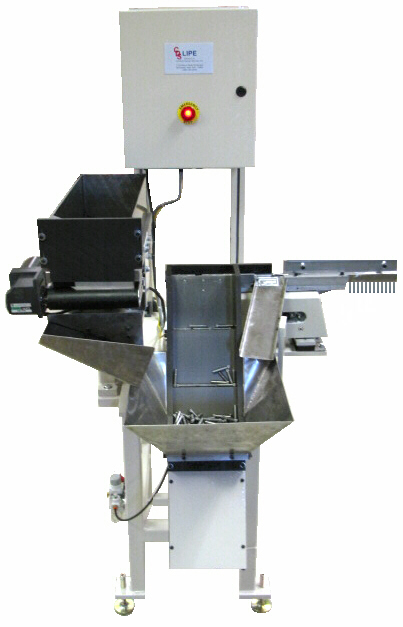

CDS LIPE Step Feeders: Quiet, Efficient, Reliable Part Feeding Systems

Quiet, Space-Saving Step Feeders for Optimal ThroughputOptimizing Throughput and Ergonomics: The Strategic Integration of Step Feeding Systems

For a process engineer, the Step Feeder represents a sophisticated alternative to traditional vibratory bowls, particularly when the project requirements prioritize footprint optimization, noise reduction, and the handling of oily or heavy components.

Geometric and Material Versatility

Unlike vibratory feeders that rely on friction and surface frequency, step feeders utilize a mechanical lifting motion. This makes them the superior choice for:

High Aspect Ratio Parts: Step feeders are ideally suited for pins, shafts, and cylinders that require specific linear orientation.

Contaminated Components: Step feeders excel at feeding "oily" or "greasy" automotive parts that would typically cause a vibratory bowl to lose its coefficient of friction and stall.

Delicate Surface Finishes: The gentle, reciprocating lifting action of our step feeders minimizes part-on-part impingement, preserving the integrity of plated or polished surfaces.

Spatial Efficiency and Ergonomics

Step feeders are inherently vertical. For a process engineer managing floor space (cost per square foot), they offer a distinct advantage:

Integrated Bulk Storage: Most CDS Lipe step feeders combine the storage hopper and the orientation mechanism into a single, compact footprint.

Low Loading Heights: Because the "steps" begin at a low elevation, they can often be loaded manually or by an automated bin tipper without the need for high-reach platforms or secondary elevators, directly addressing ergonomic safety standards.

Step Feeders are perfect for automatic parts feeding and presentation of parts for assembly, inspection or secondary application. CDS LIPE step feeder systems are used heavily in the automotive industry and known for their flexibility, efficiency, and day to day reliability. Quiet and efficient, our step feeders provide efficient parts feeding and orientation quietly and consistently.

Step Feeder shown top right equipped with linear vibratory output track.

STEP FEEDER FEATURES

- Quiet Operation

- Low Maintenance

- Metered Feeding

- Gentle Handling

- Vibration Free Feeding

- Feeds a Wide Variety of Parts

- Handles Oily and Contaminated Parts

- Low Load Height

- Simple Reliability