Understanding Step Feeders: The Gentle Giants of Material Handling

Step feeders are a type of vibratory feeder used for the gentle and efficient handling of a wide variety of bulk components. They are particularly well-suited for parts that are fragile, oily, or have complex geometries, where traditional bowl feeders might cause damage or jams. CDS-LIPE specializes in the engineering and manufacturing of these robust systems to deliver reliability and performance in automated production lines.

What are Step Feeders?

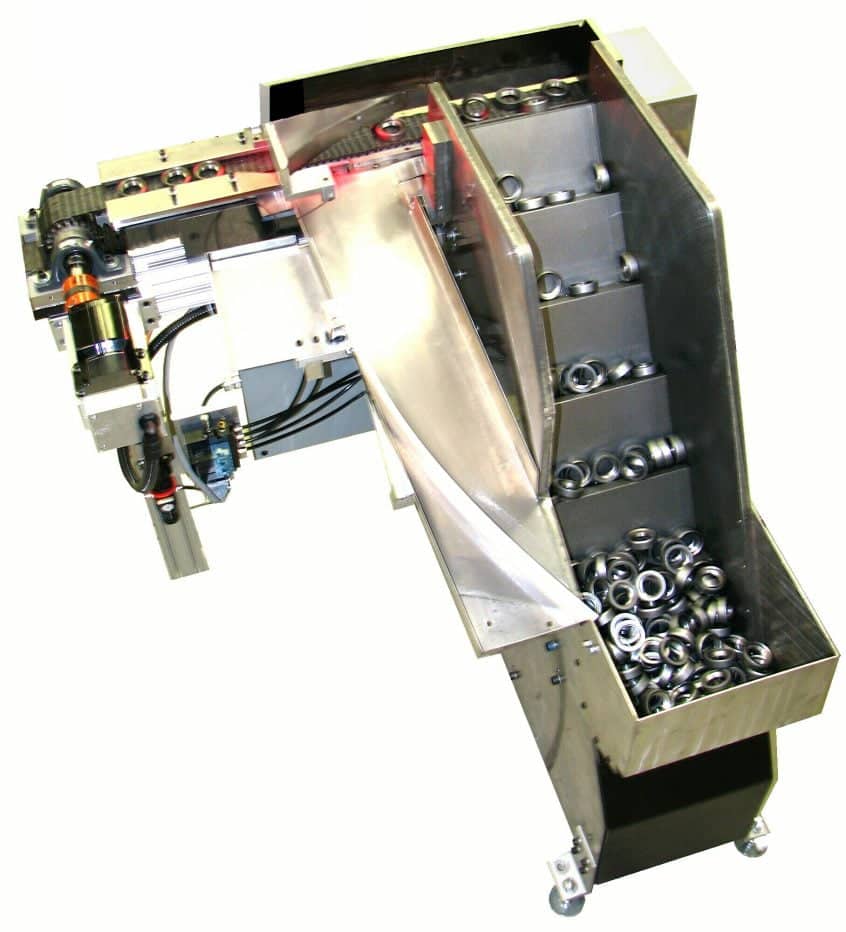

Unlike bowl feeders that use a spiral track, a step feeder utilizes a series of inclined plates, or “steps.” When the system’s vibratory drive unit is activated, these steps lift and advance parts with a controlled, gentle motion. Parts at the bottom of the hopper are carried up by the steps, while excess or incorrectly oriented parts simply fall back down. Only properly oriented parts make it to the top level, where they are then discharged onto a linear track for the next stage of the assembly process.

This unique mechanism makes step feeders ideal for:

- Handling Fragile Parts: The gentle lifting and minimal contact between parts prevent scratching, chipping, or other damage.

- Dealing with Oily or Contaminated Parts: Unlike vibratory bowls where parts can stick or clump together, the stepping action effectively separates parts.

- Accommodating a Wide Range of Part Sizes and Shapes: Step feeders are highly versatile and can be configured to handle components from small dowel pins to much larger, heavier industrial parts.

How are they Used?

Step feeders are an indispensable part of automated material handling and are used in a variety of industries where high-speed, gentle feeding is a priority. Their primary function is to store, elevate, and orient parts for subsequent processes.

Common applications include:

- Automotive Industry: Feeding components like bearings, washers, and brake parts.

- Machining and Stamping Operations: Supplying a steady flow of newly machined or stamped parts to the next process.

- Hardware Manufacturing: Handling fasteners, nuts, and other metal components.

By providing a reliable and gentle feeding solution, step feeders contribute significantly to the overall efficiency and quality of a production line. They reduce product waste, minimize downtime due to part jams, and ensure a continuous supply of correctly oriented components for high-speed assembly and manufacturing.