Dyna-Slide: Premier Gentle Parts Feeders & Materials Handling Equipment

The Dyna-Slide technology from CDS Lipe is the industry-leading solution for gentle, high-efficiency material handling. Developed since 1972, Dyna-Slide systems are specifically engineered to handle parts that are fragile, finished, green (unsintered powdered metal), or have highly sensitive surfaces that other feeders would scratch or damage.

The core distinction of Dyna-Slide is its combination of directional linear vibration with a revolutionary Brushlon surface. It creates a gentle wave motion that conveys and orients parts quietly and safely without contact-induced wear. CDS Lipe provides this technology across a versatile range of components, from single feeders to complex, integrated systems.

Key Features of Dyna-Slide Gentle Part Handling

- Non-Marking & Non-Scratching: The Brushlon surface acts as a cushion, allowing fragile or polished parts. Parts like glass, ceramics, finished machined components, or delicate electronic parts move with minimal risk of surface damage.

- Quiet Operation: Dyna-Slide systems typically operate at less than 65 dBA, creating a significantly quieter work environment than many conventional vibratory systems.

- Flexible and Adaptable: Simple tooling changes allow Dyna-Slide systems to feed families of parts. This includes square, near-square, or difficult-to-orient components—in a single feeder, a capability often impossible for standard vibratory bowls.

- Multi-Functionality: The technology is integrated into various equipment types for diverse purposes.

- Feeding & Orienting: Linear feeders for precise part presentation (e.g., to grinders or marking systems).

- Accumulation: Gentle accumulation tables and vibratory accumulators provide zero back pressure buffering for larger or heavy components, essential for line balancing and fault bypass.

- Transport & Processing: Conveyors used for transfer, part rotation (rifling), de-burring, de-dusting, and part washing applications.

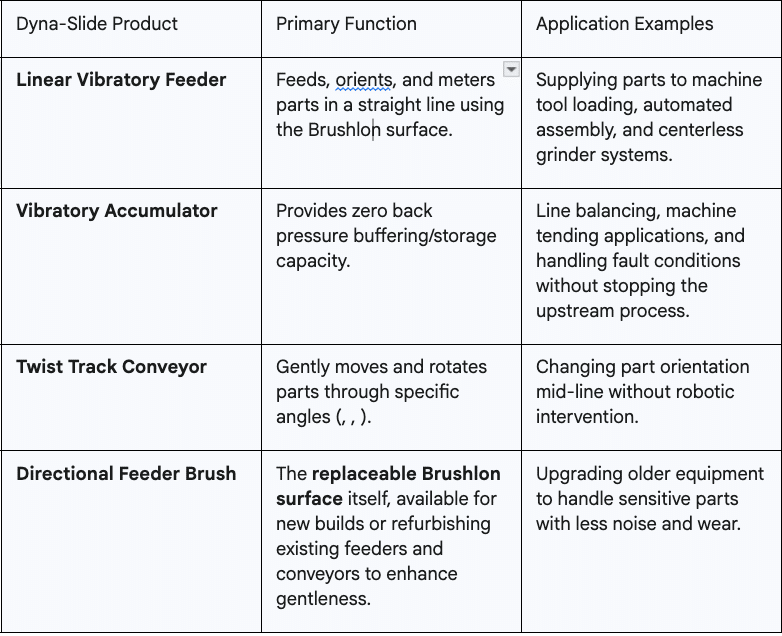

Dyna-Slide Product Portfolio Overview

Frequently Asked Questions (FAQ)

Q: Can Dyna-Slide handle finished machined parts without marking the surface?

A: Yes. Dyna-Slide technology was specifically designed in the 1970s for handling fragile, finished, or sensitive surfaces. The Brushlon material and gentle linear vibration eliminate the abrasion and high-impact contact associated with standard steel or plastic feeder bowls.

Q: Can a Dyna-Slide feeder be retooled for a new part?

A: Absolutely. Dyna-Slide is a renewable technology. Thousands of units have been successfully refurbished and retooled for new parts, packages, or materials, making it a sustainable and cost-effective long-term investment.

Q: Is Dyna-Slide suitable for machine tending applications?

A: Yes. Dyna-Slide feeders, conveyors, and accumulators are proven solutions for assembly integration, machine tool loading (e.g., centerless grinders), robot integration, and general machine tending applications requiring reliable and gentle part presentation.

Q: How quiet are these systems?

A: A typical Dyna-Slide linear feeder or conveyor operates at less than 65 dBA, contributing to a quieter and safer working environment compared to many high-speed feeders.