What are Pre-Feeders?

Pre-feeders are material handling devices designed to store and transfer bulk components to a feeder bowl (either vibratory or centrifugal) as needed. Their primary function is to maintain a constant, low-level supply of parts in the main feeder bowl, preventing it from running empty. This continuous operation eliminates the need for frequent manual reloading, which can be a significant bottleneck in a production line.

How They Work

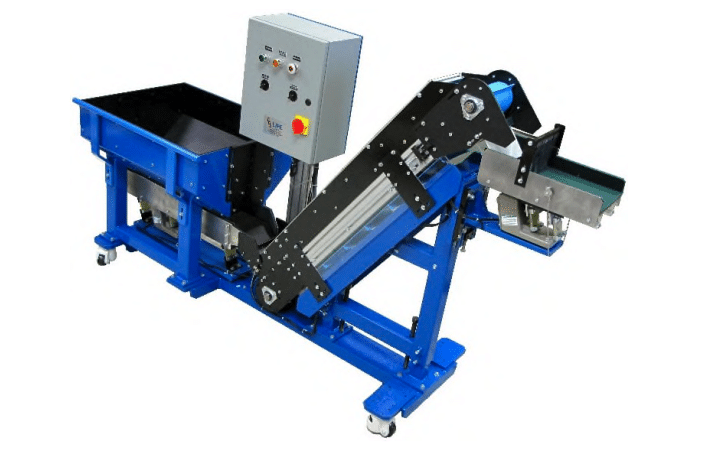

A typical pre-feeder system consists of a large hopper or storage bin, often with an integrated vibratory or inclined conveyor. When the level of parts in the main feeder bowl drops below a set threshold (detected by a sensor), the pre-feeder automatically activates. It then conveys a controlled amount of parts from its hopper into the bowl, ensuring the bowl remains adequately filled for continuous operation. This automated process is key to maximizing uptime and overall line efficiency.

Key Features and Advantages

- Increased Uptime and Efficiency: By automatically replenishing the feeder bowl, pre-feeders eliminate production stops for manual refilling. This keeps the assembly line running smoothly and consistently at its maximum speed.

- Reduced Labor Costs: Automating the feeding process frees up personnel who would otherwise be tasked with constantly monitoring and refilling the bowls, allowing them to focus on more complex, value-added tasks.

- Gentle Part Handling: Pre-feeders can be designed to handle parts gently, minimizing damage to delicate components. This is especially important in industries like medical and pharmaceutical, where product integrity is critical.

- Bulk Storage: They provide a large buffer of parts, allowing for long periods of unattended operation. This reduces the frequency of operator intervention and makes the entire system more reliable.

- FDA-USDA Approved Design: As mentioned, CDS-LIPE’s pre-feeders are designed to meet stringent FDA-USDA standards. This is a crucial selling point for clients in the food, pharmaceutical, and medical industries where hygiene and sanitation are paramount. These designs often feature stainless steel construction, smooth welds, and easy-to-clean surfaces to prevent contamination and bacterial growth.

- Range of Sizes: Offering a wide range of sizes, from 6″ to 54″ in diameter, allows CDS-LIPE to provide a solution that is perfectly scaled to the client’s needs, whether they are handling tiny electronic components or larger industrial parts. This flexibility ensures the system is neither under- nor over-engineered for the specific application.

Why They are Crucial for Automation

Pre-feeders are an essential element of a fully integrated and automated material handling system. They are the link between bulk storage and the precision-feeding equipment. Without a pre-feeder, even the most advanced feeder bowl would be limited by the speed and consistency of manual loading. By ensuring a steady supply of material, pre-feeders allow the entire assembly line to operate at its peak performance.

Have a new project or one that is having more down time than you want, talk to us.