Vibratory Conveyors: The Foundation of Consistent Material Flow

Vibratory conveyors are robust material-handling equipment essential for transporting bulk products, parts, and materials across a wide range of industries. They function by using controlled vibratory force to gently move fine to coarse-grained bulk materials, ensuring a consistent and uninterrupted flow into subsequent manufacturing processes.

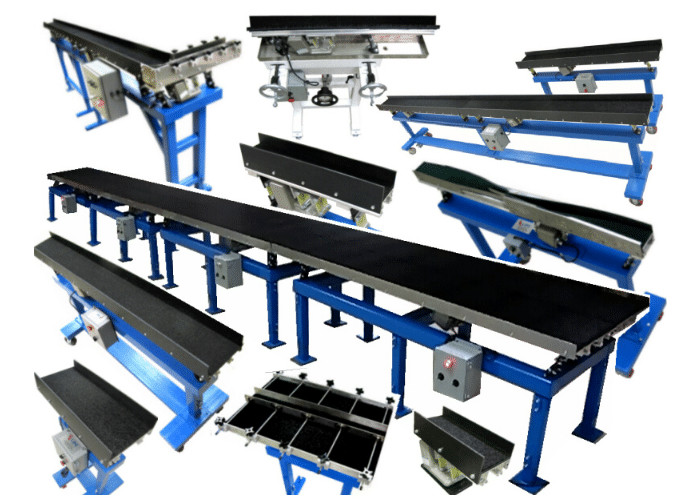

CDS Lipe is an expert manufacturer, designing and building heavy-duty, customized Vibratory Conveyors engineered for precision, durability, and seamless integration into high-volume production environments.

What is a Vibratory Conveyor?

A Vibratory Conveyor is an apparatus that utilizes a drive mechanism (either electromagnetic or electromechanical) to generate directional, rapid vibrations in a trough or pan. This repetitive motion, which combines a subtle upward and forward thrust, causes the material to be propelled forward in a continuous series of micro-hops or slides.

- Continuous Flow: They ensure a steady, measurable flow rate of material, crucial for maintaining consistency in mixing, batching, and processing.

- Gentle Handling: The controlled tossing action minimizes product degradation and breakage, making them ideal for delicate products like food, cereals, or fragile components.

- Harsh Environment Capability: With minimal moving parts (no rollers, belts, or return mechanisms), they are inherently durable and can withstand high temperatures, abrasive materials, and corrosive substances.

How are Vibratory Conveyors Used?

Vibratory Conveyors are utilized to solve complex material movement challenges across diverse industrial sectors:7

- Bulk Material Transport: Used in mining, quarrying, and recycling to move heavy, abrasive materials like ore, aggregates, or scrap metal over short to moderate distances.

- Product Alignment and Spreading: In food and pharmaceutical industries, they are used to gently align and spread products evenly before packaging, cooking, or inspection stages.

- Multi-Purpose Processing: Beyond simple transport, these conveyors can be equipped with screens or perforated sections to simultaneously screen, dewater, or cool materials as they move along the line.

Hygienic Applications: Constructed from stainless steel with smooth, non-porous surfaces, they meet stringent sanitary standards for food, beverage, and pharmaceutical processing.

CDS Lipe: Engineering for Industrial Reliability

CDS Lipe’s position as a premier manufacturer comes from engineering Vibratory Conveyors that are custom-tailored for peak operational performance:12

- Robust Construction: Our conveyors are built with heavy-duty construction to withstand the most demanding 24/7 manufacturing environments, ensuring long life and reliability.

- Custom Tooling: We offer solutions that integrate specialized features like enclosed troughs for dust containment, custom coatings for sticky materials, and precise sizing for part separation.

- Integration Experts: CDS Lipe designs these conveyors to seamlessly interface with our full range of parts handling equipment, including bulk supply feeders, inspection machines, and accumulator tables, ensuring a perfectly integrated production flow.