Dyna-Feed - Part Feeding Materials Handling Equipment & Systems

Optimizing Assembly with Dyna-Feed - Part Feeding

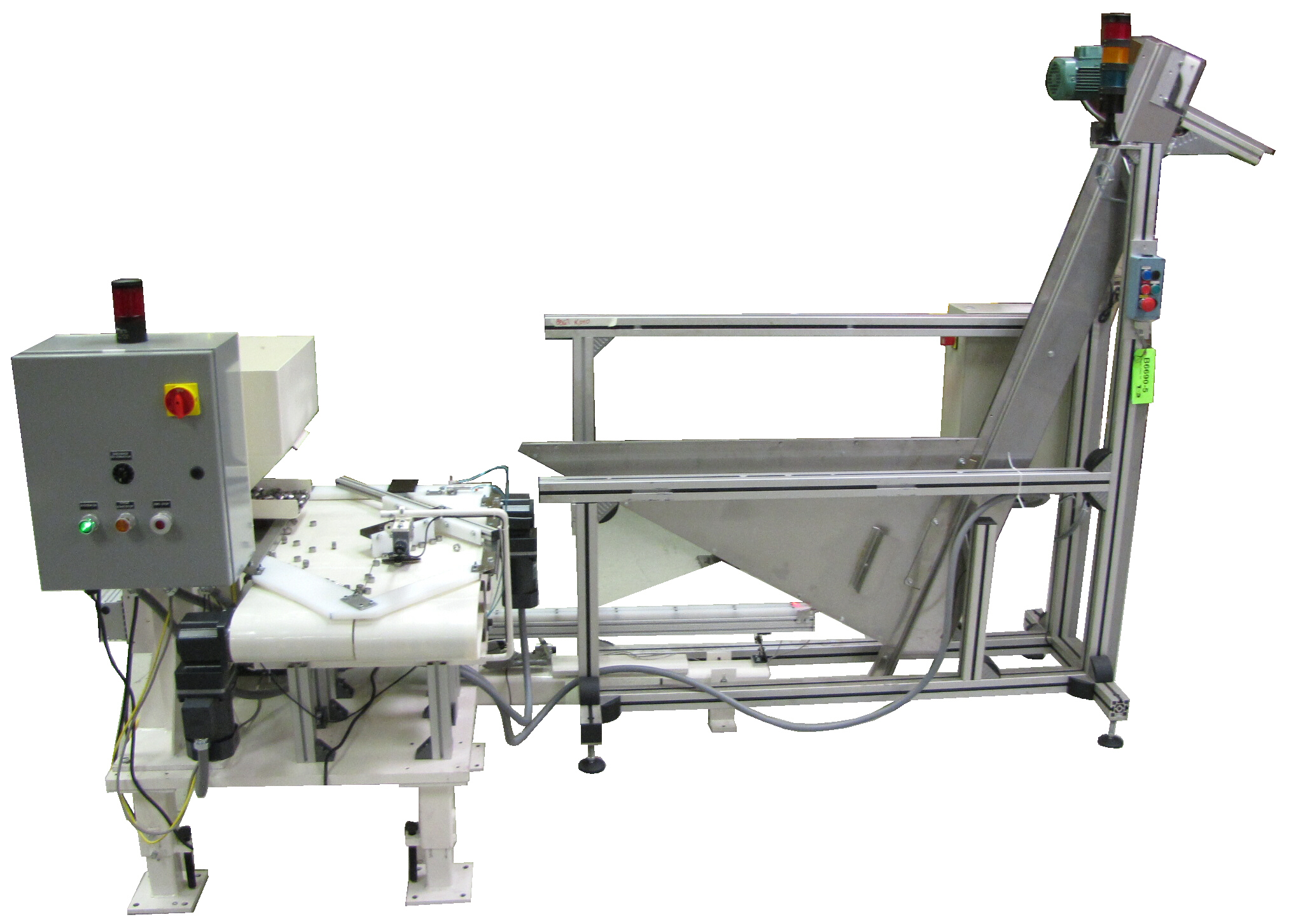

CDS-LIPE standard part feeding products include Step Feeders, Vibratory Bowl Feeders & Rotary Feeders, Separators, Orientors /Hoppers/Pans/Screen Feeders/Bulk Supply Systems.. .

Building Blocks- We build quality, integrated handling equipment and systems that move , feed, accumulate and orient parts, packages or materials to automate your process.

Dyna-Feed - Part Feedingrefers to the strategic use of integrated equipment to move, orient, and deliver components to an automated production line. These systems utilize specialized hardware like step feeders and vibratory bowls to ensure a continuous flow of materials for high-speed manufacturing. Consequently, Dyna-Feed - Part Feedingminimizes manual intervention and maximizes overall equipment effectiveness (OEE).

Why Process Engineers Prioritize Dyna-Feed - Part Feeding

Reliability remains the top priority for any process engineer building an assembly line. Therefore, selecting the right Dyna-Feed - Part Feedingsolution is essential for operational success. CDS LIPE serves as a premier automated material handling systems expert with decades of industry experience. We provide "building blocks" of quality equipment that handle the most rigorous manufacturing environments.

Specifically, our systems move, feed, and accumulate parts with extreme precision. Because every project has unique requirements, our modular approach allows for rapid integration. For example, we offer various bulk supply systems to fit your footprint. Furthermore, these systems handle parts of various geometries without jamming or slowing down.

Effective Dyna-Feed - Part Feedingreduces the risk of costly downtime. If a feeding system fails, the entire robot cell stops immediately. Thus, our robust designs focus on longevity and repeatable performance. We integrate high-quality separators and orientors to maintain part integrity at all times.

Technical Components of Automated Material Handling Equipment

Modern Dyna-Feed - Part Feedinginvolves more than simple vibration. Instead, it requires a sophisticated blend of mechanical and electrical engineering. Specifically, our standard product line includes several critical technologies.

Equipment Type | Function in the Assembly Process |

Vibratory Bowl Feeders | Orient and discharge small parts in a specific position. |

Step Feeders | Lift parts from a bulk hopper to a linear track gently. |

Rotary Feeders | Provide high-speed output for cylindrical or symmetrical parts. |

Bulk Supply Systems | Store large volumes of raw materials to feed secondary units. |

Additionally, we offer specialized hoppers and pans to manage material flow. Since we utilize pre-engineered components, your team saves significant design time. Moreover, these systems integrate seamlessly with autonomous material handling protocols. By using our screen feeders, you can also filter out debris or malformed parts.

Consequently, the quality of the output remains consistently high. Furthermore, our orientors ensure that parts reach the pick-and-place station correctly every single time. Transitioning to these automated solutions helps facilities scale their production capacity quickly.

Strategic Advantages of Integrated Handling Systems

Process engineers often face tight deadlines and strict budget constraints. However, the Dyna-Feed - Part Feedingmethodology simplifies the complex task of system integration. We view our equipment as essential building blocks for your automated process.

First, our hardware improves the ergonomics of the factory floor. By automating the bulk handling of parts, you reduce the physical strain on human operators. Second, these systems offer a rapid return on investment through increased throughput. For instance, a well-tuned rotary feeder can outperform manual loading by a massive margin.

Furthermore, our Dyna-Feed - Part Feedingunits are built to withstand 24/7 operations. Because we use durable materials, the maintenance requirements stay very low over time. Similarly, the flexibility of our hoppers allows for easy changeovers between different product lines. This adaptability is crucial in the modern era of high-mix, low-volume manufacturing.

Expert Q&A: Precision in Part Feeding

- How does Dyna-Feed - Part Feeding improve robot cycle times?

It delivers parts in the exact orientation needed, which eliminates the time a robot spends searching for or adjusting a component.

- What is the benefit of a step feeder over a vibratory bowl?

Step feeders are often quieter and gentler on delicate surfaces while handling parts that might tangle in a traditional bowl.

- Can these systems handle autonomous material handling for heavy parts?

Yes, our heavy-duty bulk supply systems and separators are engineered to manage significant weights with high reliability.

- How does CDS LIPE ensure part orientation accuracy?

We use custom-tooled tracks and specialized orientors that mechanically reject any part not meeting the specified alignment.

- Are these feeding systems compatible with smart factory sensors?

Absolutely, our equipment integrates easily with part counters and level sensors to provide real-time data to your control system.

CDS LIPE provides the expert engineering and durable equipment needed to automate your most challenging material handling processes.

Perfect for automatic feeding and presentation of parts for any assembly, inspection or secondary application.

Perfect for automatic feeding parts to grinders, induction heaters, thread rollers, cappers, marking systems extrusion press operations and other process and assembly systems.

Intelligent Bulk Part Supply Automation

We've automatically metered parts and materials from every type of container "on demand" from uranium pellets, grain, abrasives, light bulbs, plier handles and thousands of parts in between.

CDS LIPE designs and builds vibratory bowl feeder systems since the 1970's as well as the Dyna-Slide line of linear vibratory parts feeder systems capable of handling a broad range of parts. Hopper, tracks and roll sorters are available as ancillary elements which can be added to complete your project.

Fills the niche between long bar feed and orientation feeders. Magazine feeders take many forms.

Low Level Hopper/Elevator/Feeder

A hopper/feeder/ elevator is very effective on simple parts. Hopper elevators supply parts, packages and materials to rotary feeders, vibratory feeders, belt feeders and process machinery

Vibratory bulk storage feeders are available for supply dosing and disentangling of parts, materials and packages. Storage feeders are available with flow control features to control the supply of parts and materials into feeders or downstream automation.

Centrifugal Feeder Bowls range in size form 6" in diameter to 54" in diameter, and are offered in both USDA approved design and industrial grade design.

Taper Wall & Straight Wall Supply Hoppers

Vibratory supply hoppers are designed for the controlled feeding of bulk parts and materials into feeders or machines.

Discharge conveyor can take many design forms including flat vibratory linear, V-track, rail, rod, vibratory pan, belt, indexing belt, precision servo belt, table top chain

Vibratory hoppers are available in multiple designs including high capacity ( 8,000 lb) impact pans with AR Liners for highly abrasive parts.

Drop Bottom Stand w/ Container-Auto Unloader

Vibratory pans combined with drop bottom stand are available in multiple designs including high capacity ( 8,000 lb) impact pans with AR Liners for highly abrasive parts to meter parts to upstream process.

Part, Package and Material Distribution Pans

Vibratory pans are available to distribute parts, packages or materials to downstream process. Can be integrated to inspection systems, vision guided robots and packaging systems.

Safety Guarding, Dust Enclosures and Sound Control Enclosures are available for every machine or system.

Roll Sorters are produced by our Sister Plant CDS Mfr. These precision roll sorters (also referred to as roller sorters and roller micrometers) are perfect for precise tight tolerance sorting.