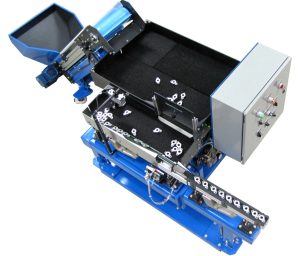

Dyna-Slide Gentle Parts Feeders & Materials Handling Equipment

Gentle Parts Feeders & Materials Handling Equipment are not merely accessories for an assembly line; they are the core technology required to maximize product quality and virtually eliminate yield loss associated with automated production. In the high-speed environment of modern manufacturing, a smooth process is impossible without feeders that can handle parts without damage.

Why Gentle Handling is Critical to Your Assembly Line

The importance of gentle handling parts feeding equipment is defined by three factors that directly impact your bottom line:

- Protecting High-Value Parts:Many modern components—such as finished machined parts, glass, ceramics, delicate electronic parts, or green (unsintered) powdered metal components—are extremely sensitive to scratching, chipping, or deformation. Traditional, aggressive vibratory feeder systems can turn minor components into expensive scrap. Gentle vibratory feeders eliminate this costly damage.

- Maintaining Quality and Consistency:Automated assembly and inspection machines rely on components being presented in perfectcondition. A gentle vibratory feeder ensures the part's integrity (e.g., no micro-fractures, no surface abrasion), guaranteeing that the final product meets stringent quality specifications, especially in medical and automotive sectors.

- Maximizing Uptime (Zero Back Pressure):Vibratory feeder systems built for gentle handling often feature zero back pressure accumulation. This means parts are never jammed or crushed while waiting for the next station. By eliminating the root cause of jams, the equipment ensures a continuous flow, which is crucial for achieving high Overall Equipment Effectiveness (OEE).

Key Features of Dyna-Slide Gentle Part Handling

The Dyna-Slidetechnology from CDS Lipe

The Dyna-Slidetechnology from CDS Lipeis the industry-leading solution for gentle, high-efficiency material handling.Developed since 1972, Dyna-Slide vibratory feeder systems can handle parts that are fragile, finished, green (unsintered powdered metal), or have highly sensitive surfaces that other feeders would scratch or damage.

The core distinction of a Dyna-Slide gentle parts feeder is its combination of directional linear vibration with a revolutionary directional vibratory feeder brush surface, creating a gentle wave motion that conveys and orients parts quietly and safely without contact-induced wear.CDS Lipe provides this technology across a versatile range of components, from single parts feeders to complex, integrated systems.

Non-Marking & Non-Scratching:

- The directional vibratory feeder brush surface acts as a cushion, allowing fragile or polished parts (like glass, ceramics, finished machined components, or delicate electronic parts) to move with minimal risk of surface damage.

Quiet Operation:

Dyna-Slide vibratory parts feeder systems typically operate at less than 65 dBA, creating a significantly quieter work environment than many conventional vibratory systems.

Flexible and Adaptable:

- Simple tooling changes allow Dyna-Slide vibratory parts feeders to feed families of parts—including square, near-square, or difficult-to-orient components—in a single feeder, a capability often impossible for standard vibratory bowls.

Multi-Functionality:

- The technology is integrated into various equipment types for diverse purposes:

Feeding & Orienting:

- Linear vibratory parts feeders for precise part presentation (e.g., to grinders or marking systems).

- Gentle accumulation tables and vibratory accumulators provide zero back pressure bufferingfor larger or heavy components, essential for line balancing and fault bypass.

- Conveyors used for transfer, part rotation (rifling), de-burring, de-dusting, and part washing applications.

The CDS Lipe Advantage: Engineered for Gentleness

Purchasing Gentle Parts Feeders & Materials Handling Equipment from CDS Lipeprovides a crucial competitive advantage because the company’s solutions are founded on proprietary technology and comprehensive expertise:

- Proprietary Dyna-Slide Technology:CDS Lipe utilizes its signature Dyna-Slide technology, which combines directional linear vibration with a unique directional vibratory feeder brush surface. This creates a wave motion that conveys parts quietly and safely, minimizing abrasive contact that leads to part marking.

- Integrated Quality Assurance:CDS Lipe feeder systems go beyond simple feeding. They are often integrated with high-speed vision and inspection systemsthat provide real-time quality control anduse gentle rejection mechanisms. Non-conforming or mis-oriented parts are often returned in a zero drop horizontal attitude, protecting even the most delicate components from damage during the rejection phase.

- Versatile Flexibility:With systems like the Dyna-Slide Linear Vibratory Parts Feederand Flexible Feedertechnology, CDS Lipe offers quick-change toolingand the ability to handle entire families of parts(even those that are square or near-square) in a single unit. This agility drastically reduces downtime and capital investment for high-mix production.

By choosing CDS Lipe, you are investing in a proven, non-marking, low-noise parts feeding solutionthat reduces rework, minimizes yield loss, and optimizes the assembly line to run at its highest potential quality and speed.

Dyna-Slide gentle parts feeders have been doing what no other material handling technology can do since 1972. Designed for fragile, green or sensitive surfaces and can gently accumulate, feed and orients parts, packages and materials for automated processing. The "original flexible automation" with thousands of units in operation many of them handling finished machine parts, green powdered metal, glass and ceramic parts and materials. Dyna-Slide is a well known industry leader for gentle parts feeders. Dyna-Slide gentle parts feeders combine linear vibration with a directional vibratory feeder brush surface to create a gentle vibration wave motion. Simple quiet, safe, non-marking Dyna-Slide parts feeders are ideal for your value added application.

Dyna-Slide Vibratory Parts Feeders & Orientors can feed families of parts with simple tooling and have the unique ability to incorporate quick change tooling capable of handling square, undersquare and near square parts in a single feeder. Available in a wide range of sizes which can feed parts, packages or materials that feeder bowls simply are incapable of feeding.

Dyna-Slide Vibratory Conveyors are so flexible they can transfer, zero back pressure accumulate, index, merge, sort and orient parts, packages and materials.

Dyna-Slide Vibratory Accumulators & Buffers are suitable for larger and heavy components and are proven to meet the challenges and changing needs of the assembly integration, machine tool loading, packaging machine loading and robot integration industries.