Understanding Vibratory Feeders: The Core of Automated Production

Vibratory feeders are specialized machines that use controlled vibration to sort and move bulk materials or individual components. As a core element of modern automation, they are essential for ensuring a smooth, consistent flow of parts in a variety of manufacturing and assembly processes. At CDS-LIPE, we are experts in designing and manufacturing these critical systems to meet the unique needs of our clients.

What are Vibratory Feeders?

Vibratory feeders are short conveyors or devices designed to transport bulk materials from a hopper or bin to a specific point in a production line. The name “vibratory” comes from their use of a powerful drive unit that creates a series of rapid, directional vibrations. These vibrations cause parts to be “tossed” forward in a precise, controlled motion. This tossing, hopping, or sliding action can be fine-tuned to handle a wide range of materials, from fine powders and granules to irregularly shaped objects.

The most common types of vibratory feeders are:

- Vibratory Bowl Feeders: These feeders are a mainstay of automated assembly. They feature a bowl with a helical track that vibrates, causing parts to climb the track. As parts move up, strategically placed tooling or features on the track reject improperly oriented items, ensuring that only correctly positioned parts exit the bowl in a single file.

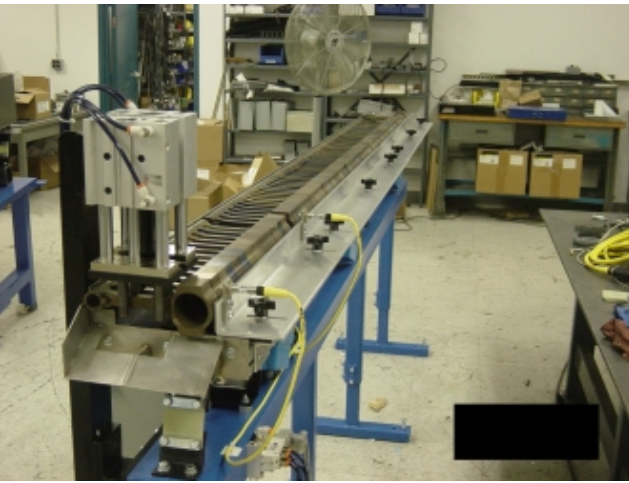

- Linear Vibratory Feeders: These feeders use a straight pan or trough to move parts over a short distance. They are often used as a secondary feeder to transport parts from a bowl feeder to a final assembly station or to create a buffer of parts.

- Vibratory Hoppers: Pre-feeders or hoppers are used to store and automatically feed bulk materials to the main feeder bowl, preventing it from running empty and maximizing production uptime.

How are Vibratory Feeders Used?

Vibratory feeders are fundamental to any automated system that requires a reliable supply of parts. Their primary use is to precisely orient, singulate, and feed components to downstream machines. Instead of relying on manual labor to sort and position parts, a vibratory feeder can perform these tasks continuously and without error at extremely high speeds.

This capability makes them indispensable in countless industries:

- Automotive: Feeding small fasteners, clips, and connectors for robotic assembly.

- Electronics: Orienting micro-components like resistors, capacitors, and screws for circuit board manufacturing.

- Pharmaceuticals: Handling and feeding pills, capsules, and bottle caps in sterile packaging environments.

- Consumer Goods: Sorting and aligning items like bottle caps, lids, and small product components.

By automating the feeding process, vibratory feeders dramatically reduce labor costs, increase production speed and consistency, and improve overall product quality by ensuring that only correctly oriented parts are used in the final product. CDS-LIPE has the expertise to design and manufacture the ideal vibratory feeding solution for your unique application.