Gentle Parts Handling Solutions utilize specialized transport mechanisms like directional linear vibration and Brushlon surfaces to move delicate components without damage. These systems protect fragile parts by minimizing contact stress and eliminating back pressure during the feeding process. Consequently, manufacturers achieve higher yields and lower scrap rates in precision electronics and medical assembly. Why Engineers Prioritize Gentle Parts Handling Solutions … Read More

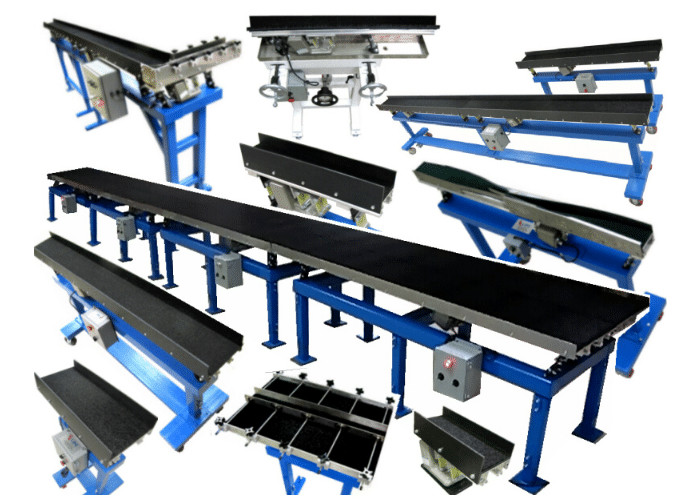

High-Performance Power Belt Conveyors for Industrial Automation

High-Performance Power Belt Conveyors for Industrial Automation Power Belt Conveyors are modular, scalable transport systems designed to move components through automated assembly and material handling environments. These systems utilize direct drive technology and positive belt tracking to ensure reliable, high-speed part conveyance. Consequently, they serve as the backbone for autonomous material handling by providing quiet, low-maintenance operation in diverse industrial … Read More

Manufacturer for Automated Conveyor Systems

Choosing the Right Feeder Manufacturer for Automated Conveyor Systems A feeder manufacturer provides the essential hardware needed to regulate the flow of bulk materials into an automated assembly line. These manufacturers design specialized systems, such as conveyors and vibratory units, to ensure consistent parts orientation and timing. Consequently, choosing an expert like CDS LIPE ensures your autonomous material handling equipment … Read More

Understanding Industrial Vibratory Bowl Feeder Options

A Guide to Types, Operation, and Applications Industrial vibratory bowl feeders are essential components in automation, designed to efficiently orient and feed parts for various manufacturing processes. This guide will delve into the types, operation, and applications of these feeders, providing insights into their significance in industrial automation. Readers will learn about the mechanics behind vibratory feeders, the different types … Read More

Selecting a Feeder Manufacturer for High-Speed Conveyor Systems

A premier Feeder Manufacturer provides specialized conveyors for automated systems that ensure precise part orientation and high-speed delivery. These essential systems utilize autonomous material handling to eliminate production bottlenecks and improve assembly line throughput. Consequently, process engineers rely on these solutions for seamless mechanical integration and long-term operational reliability. Choosing the right Feeder Manufacturer for High-Speed Conveyor Systems A premier … Read More

Conveyor Belt Automation

Conveyor Belt Automation: Integrating Intelligence for Competitive Advantage Conveyor belt automation is the application of advanced control technologies. These technologies include sensors, Programmable Logic Controllers (PLCs), robotics, and Variable Frequency Drives (VFDs). The goal is to maximize system speed, accuracy, and operational independence. It enables functions like automatic sorting, tracking, and precise product indexing. This automation significantly reduces labor costs … Read More

Automatic Conveyor Belt

Automatic Conveyor Belt: Engineering for Smart, Uninterrupted Flow An automatic conveyor belt is a material handling system. It uses sensors, Programmable Logic Controllers (PLCs), and variable speed drives (VFDs) to operate without constant human intervention. The primary benefit is the automated routing, sorting, and sequencing of products. This technology is vital for maximizing throughput, accuracy, and safety in modern logistics. … Read More

Conveyor Belt Conveyor

Comprehensive System Function and Optimization A conveyor belt conveyor describes a complete material transport system. It relies on an endless, continuous loop of belting material to move items or bulk materials between two points. Its core components are the belt, two or more pulleys, and a drive unit. This system is highly versatile, facilitating both horizontal and inclined movement. The … Read More

Machine Conveyor Belt

Precision Integration in the Production Cell A machine conveyor belt is a specialized, typically small-to-medium length conveyor. It is designed for precise product transfer, indexing, and buffering within an automated machine or work cell. The primary functions include presentation, accumulation, and synchronized transfer between automated workstations. Critical design factors are indexing accuracy, repeatability, and system compactness. CDS Lipe develops premier … Read More

Conveyor Manufacturing Companies

Conveyor Manufacturing Companies: Selecting the Right Engineering Partner Conveyor manufacturing companies are specialized firms that design, fabricate, and assemble material handling systems. A superior manufacturer offers more than just equipment. They provide application engineering expertise, ensuring the system integrates perfectly into the production line. Selection should prioritize technical competence, peer-review-accurate design, and industry-specific experience. CDS-Lipe is renowned among premier automated … Read More

Conveyor Belt Drive Design: Powering Precision and Efficiency

The Process Engineer’s Imperative: Sizing the Motor Conveyor belt drive design is the engineering process of specifying the motor, gearbox, and pulley system. This system must provide the necessary torque and speed to move the conveyor belt and its maximum load. The foundation of this design is the accurate calculation of effective belt tension (Te) and subsequent motor horsepower (P). … Read More

Understanding Vibratory Feeders

A vibratory feeder is an apparatus used in manufacturing. It uses a drive mechanism to create rapid, directional vibrations. Specifically, this mechanism is either electromagnetic or electromechanical. The device generates motion in a pan or trough. This repetitive motion combines a subtle upward and forward thrust. Consequently, the material is propelled forward in a continuous series of slides or micro-hops. … Read More

Feeder Brushes: Preventing Jams and Ensuring Precise Part OrientationConveyor Design

Conveyor Design: Engineering Efficiency and Selecting the Right Partner The Foundation of Efficient Material Handling Conveyor design is the critical engineering process of planning, calculating, and specifying a system to move materials optimally through a production or processing environment. This process directly impacts throughput, operational cost, and overall plant safety. A successful design ensures materials move reliably, minimizing bottlenecks and … Read More

Belt Conveyor Design

Belt Conveyor Design: The Engine of Industrial Throughput Belt conveyor design is the specialized engineering process of defining the system’s mechanical and operational parameters. The goal is moving bulk materials or unit loads efficiently and reliably. This design process critically involves calculating belt tension, motor horsepower, and material capacity. A precise design minimizes operational friction and maximizes energy efficiency. Furthermore, … Read More

Maximizing ROI and Managing Integration

Investment Assurance: Guaranteeing ROI and Minimizing Risk with CDS LIPE Systems The Immediate Answer CDS-Lipe offers premier automated material handling systems. For a Program Manager, the focus is on optimizing capital investment. We guarantee system reliability and minimize Total Cost of Ownership (TCO). Investing in a vibratory feeder system is not a purchase. Instead, it is a direct investment in … Read More

🛠️ The Process Engineer’s Guide to Vibratory Feeder Maintenance

Maintaining the peak performance of your vibratory feeders requires a fundamental understanding of harmonic balance. When a system loses its “tune,” it often leads to decreased feed rates, increased noise, and unnecessary wear on electromagnetic components. Consequently, regular preventative maintenance ensures your automation remains a competitive edge. CDS-Lipe stands as a premier automated material handling systems expert, providing the technical … Read More

What are Gentle Parts Feeders & Materials Handling Equipment

Dyna-Slide: Premier Gentle Parts Feeders & Materials Handling Equipment Dyna-Slide technology offers the industry-leading solution for gentle, high-efficiency material handling. CDS-Lipe developed these systems since 1972. Furthermore, Dyna-Slide specifically engineers them for sensitive parts. These include fragile, finished, or “green” (unsintered powdered metal) components. They handle parts with highly sensitive surfaces. Therefore, the system prevents the scratches or damage that … Read More

High-Performance Feeders for High-Volume Assembly Lines

An Expert Overview For high-volume assembly lines, the selection of a feeder is critical to achieving peak Overall Equipment Effectiveness (OEE). The best solutions blend speed, accuracy, and versatility to handle millions of components per year. As a Premier Automated Material Handling Systems Expert, CDS-LIPE recognizes that the ideal choice is often a custom solution that integrates the advanced capabilities … Read More

What do Vibratory Conveyors do?

Vibratory Conveyors: The Foundation of Consistent Material Flow Vibratory conveyors are robust material-handling equipment essential for transporting bulk products, parts, and materials across a wide range of industries. They function by using controlled vibratory force to gently move fine to coarse-grained bulk materials, ensuring a consistent and uninterrupted flow into subsequent manufacturing processes. CDS Lipe is an expert manufacturer, designing … Read More

Feeder Brush

Feeder Brushes: The Unsung Hero of Part Orientation Feeder brushes are a simple yet critical component in many vibratory feeder systems, particularly in bowl feeders. They are essential for ensuring that parts are not only elevated but also correctly oriented on the feed track, preventing jams and maximizing the efficiency of the entire system. At CDS LIPE, we understand the … Read More

What are Pre-Feeders?

What are Pre-Feeders? Pre-feeders are material handling devices designed to store and transfer bulk components to a feeder bowl (either vibratory or centrifugal) as needed. Their primary function is to maintain a constant, low-level supply of parts in the main feeder bowl, preventing it from running empty. This continuous operation eliminates the need for frequent manual reloading, which can be … Read More

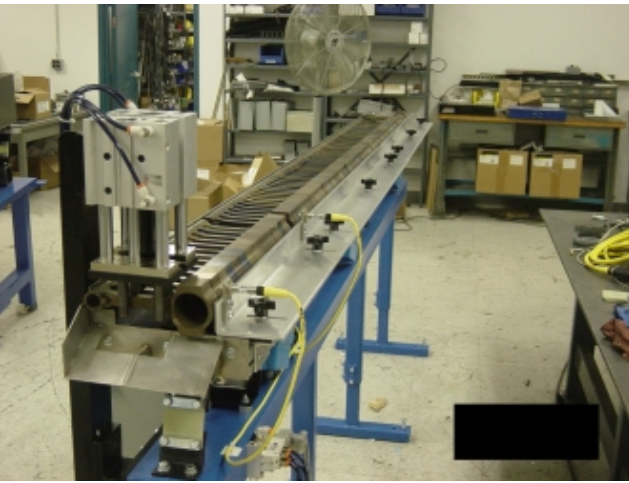

Linear Vibratory Feeders for High-Volume Production

An Expert Guide For high-volume manufacturing, selecting the “best” linear vibratory feeder isn’t about choosing a single off-the-shelf model; it’s about securing a custom-engineered system perfectly designed for your specific parts and continuous production demands. The optimal choice comes from a leading manufacturer that can provide a robust, reliable, and efficient solution that scales seamlessly with your output. CDS-LIPE, as … Read More

Physical and Mechanical Integration

CDS-LIPE’s sorting machines are designed for seamless integration with existing production lines through careful engineering of their interfaces and control systems. Here is a breakdown of how they achieve this integration: Physical and Mechanical Integration Custom Infeed and Outfeed Systems: The core of integration lies in matching the sorting machine’s inputs and outputs to your existing line. CDS-LIPE designs custom … Read More

Understanding Vibratory Feeders

Strategic Implementation of Industrial Vibratory Feeders Industrial Vibratory Feeders are specialized machines that utilize controlled, directional vibration to sort, orient, and transport bulk materials or individual components. These systems function as the heart of modern automation by ensuring a consistent, single-file flow of parts into downstream robotic cells. Consequently, they eliminate manual sorting errors and significantly enhance overall equipment effectiveness … Read More

Vibratory Feeders and Parts Handling:

Essential for Efficient Production Vibratory feeders and associated parts handling systems are the unsung heroes of modern manufacturing, transforming bulk components into a continuous, single-file stream of accurately positioned parts. As experts in this field, CDS-LIPE engineers and manufactures a tremendously diverse portfolio of machines dedicated to mastering the challenges of automated parts handling. The Importance in Efficient Production Lines … Read More

Belt Conveyors

Belt Conveyors: The Workhorse of Material Transport Belt conveyors are fundamental to modern material handling, providing a reliable and efficient means of transporting products and materials within a facility. Their versatility, reliability, and simplicity make them the most widely used type of conveyor in nearly every industry. At CDS-LIPE, we design custom systems to seamlessly integrate with your production line. … Read More

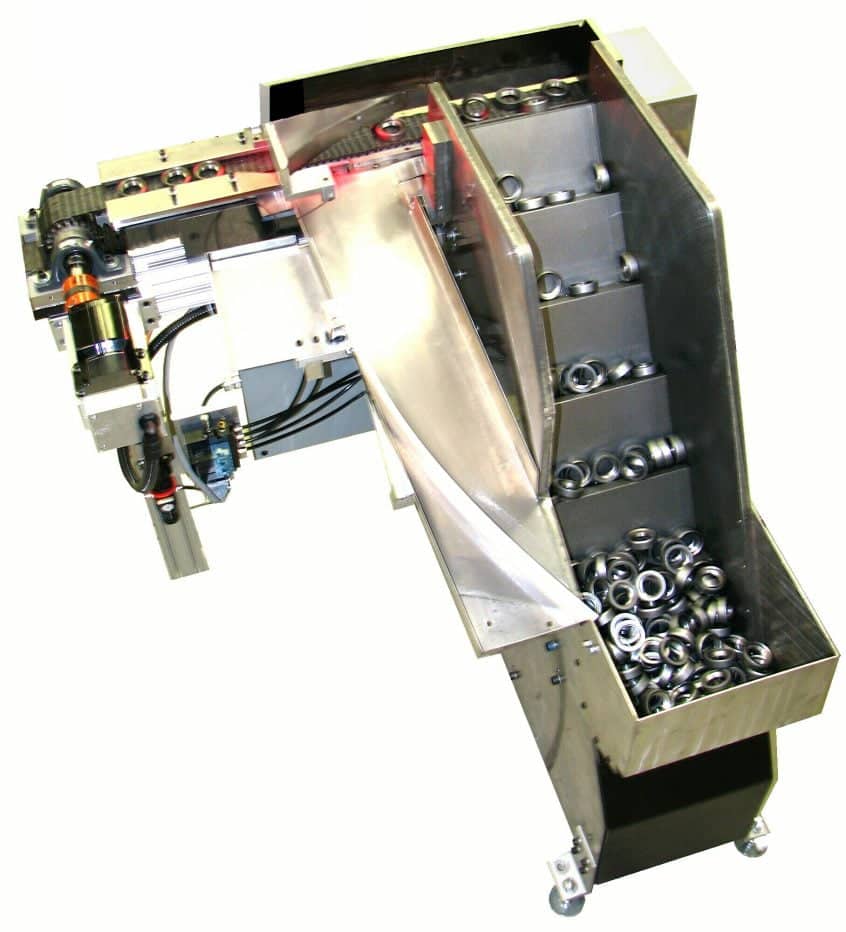

Understanding Step Feeders

Understanding Step Feeders: The Gentle Giants of Material Handling Step feeders are a type of vibratory feeder used for the gentle and efficient handling of a wide variety of bulk components. They are particularly well-suited for parts that are fragile, oily, or have complex geometries, where traditional bowl feeders might cause damage or jams. CDS-LIPE specializes in the engineering and … Read More

Strategic Implementation of Assembly Automation

Assembly Automation in medical device manufacturing involves the use of mechanized systems to perform repeatable assembly, inspection, and packaging tasks with high precision. These systems integrate controlled feeders, robotic placement, and vision inspection to reduce variability and human-induced defects. Consequently, manufacturers achieve consistent quality, higher yields, and full traceability required for ISO 13485 and FDA compliance. Why Process Engineers Prioritize … Read More

Sorting Machines

Precision and Quality in Automation Sorting machines are the final arbiters of quality in an automated production line. These sophisticated systems are engineered to inspect and categorize products or parts at high speeds, ensuring that only components meeting strict quality standards move forward. At CDS-LIPE, we design and build custom sorting machines that provide an essential layer of quality control … Read More

Supply Systems

Supply Feeders: The Foundation of Uninterrupted Production Supply feeders, also known as pre-feeders, are the crucial first step in any high-speed automated assembly line. They function as the bridge between bulk material storage and the precision-feeding equipment, ensuring a continuous and consistent supply of parts. At CDS-LIPE, we design and manufacture robust supply feeders that are essential for maximizing the … Read More

Accumulators

Accumulators: The Buffer for Seamless Production Accumulators are vital components in automated production lines, acting as a temporary storage buffer for products or parts. They are designed to absorb fluctuations in the speed of an assembly line, preventing downstream equipment from being starved of materials or from being overwhelmed. This buffering capability is essential for maximizing efficiency and ensuring continuous, … Read More

Flexible Feeders

Flexible Feeders: The Future of Versatile Automation In an era of increasing product diversity and demand for shorter production runs, traditional part feeding systems face significant challenges. Flexible feeders represent a revolutionary approach to automated material handling, offering unmatched versatility and adaptability. At CDS-LIPE, we are at the forefront of this technology, providing systems that are engineered to meet the … Read More

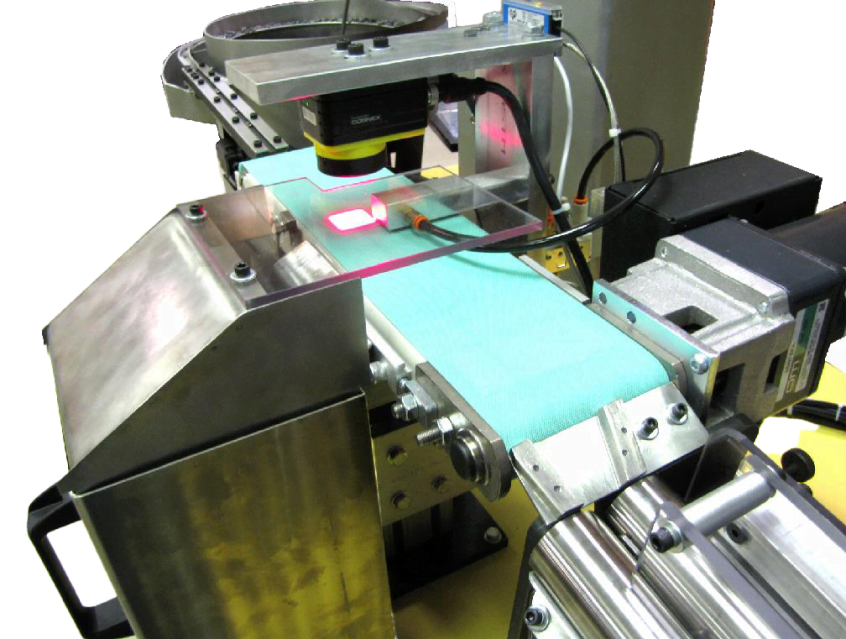

Small Part Flex Feeder

Small Part Flex Feeders: The Agile Solution for Automation Small Part Flex Feeders represent the cutting edge of automated parts handling, offering a versatile, vision-guided alternative to traditional mechanical feeders. For engineers designing modern assembly lines, these systems are essential for managing production complexity and frequent changeovers. CDS Lipe, as a Premier Automated Material Handling Systems Expert, designs and integrates … Read More

Applications in Medical Device Manufacturing

Exploring Assembly Automation and Delicate Component Handling for Enhanced Production Medical device assembly automation refers to the use of mechanized systems to perform repeatable assembly, handling, inspection, and packaging tasks for medical products, improving precision and consistency across production. This article explains how automation solves delicate component handling challenges, reduces surface damage, and raises yield for devices such as surgical … Read More

Strategic Implementation of Industrial Vibratory Feeders

Industrial Vibratory Feeders are specialized machines that utilize controlled, directional vibration to sort, orient, and transport bulk materials or individual components. These systems function as the heart of modern automation by ensuring a consistent, single-file flow of parts into downstream robotic cells. Consequently, they eliminate manual sorting errors and significantly enhance overall equipment effectiveness (OEE). The Engineering Logic of Vibratory … Read More